Sales hotline

Sales hotline

Home >> Products >> Inorganic chemicals

Indicator: parameter value

Chemical formula: SiO₂·nH₂O

CAS number: 112926-00-8

Pore size distribution: 2-50nm (customizable)

Specific surface area: 300-800 m²/g (BET method)

Water absorption (25℃): ≥30% (RH=90%, ASTM D2842)

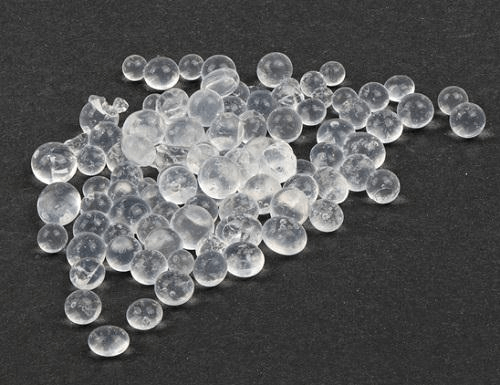

Morphology: granules/spheres/powder (3-7mm optional)

Industry Solutions:

Electronic moisture-proof: 1kg silica gel can protect 1m³ space (RH<10%), suitable for precision instruments/IP67 packaging

Chromatographic separation: 5μm spherical silica gel filler (C18 bonded phase) improves HPLC separation efficiency (plate number>15,000/m)

Industrial catalysis: as a catalyst carrier (such as palladium-loaded type), the porosity is controllable (>90%), and the reaction conversion rate is increased by 25%

Food drying: FDA-certified, used for medical bottles and seaweed packaging, no migration pollution risk

Silicone gel is a type of low cross-link density silicone rubber without fillers. Different from ordinary silicone rubber elastomers, silicone gel is transparent or translucent gel-like in appearance, with very low mechanical strength and hardness that is difficult to measure. Its physical strength is generally characterized by needle penetration. In addition to the advantages of general organic silicon materials such as high and low temperature resistance, safety and non-toxicity, good biocompatibility, and good electrical insulation performance, silicone gel also has the properties of gel-like substances such as vibration absorption, adhesion, and sealing.

Since silicone gel has good cushioning properties, can be colorless and transparent, easy to adjust performance, convenient processing and molding, good fluidity, and easy to fill fine structures, it has been widely used in medical prostheses, medical dressings, electronic and electrical potting and other fields. The application of silicone gel in the field of daily necessities has also developed rapidly, mainly by utilizing the non-toxic and non-irritating and cushioning and vibration-absorbing properties of silicone gel. Silicone gel has been used in the market as a sole cushion, seat cushion, underwear lining and other products.

A method for preparing a stable high thermal conductivity silicone gel comprises the following steps:

S1: 95g of divinyl polydimethylsiloxane with a viscosity of 500mPa·s and 0.002g of divinyl tetramethyl disiloxane platinum complex are mixed evenly to obtain gel A; 75g of divinyl polydimethylsiloxane with a viscosity of 1000mPa·s, 8.2g of terminal methyl side hydrogen silicone oil, 3g of terminal hydrogen silicone oil, and 0.0003g of ethynyl cyclohexanol are mixed evenly to obtain gel B;

S2: 3g of polyamide wax powder prepared in Preparation Example 1, 8g of montmorillonite, 1.0g of propylene glycol alginate, 1.6g of hydroxymethyl cellulose, 2210g of thermal conductive powder, and 70g of flame retardant are mixed at a temperature of 25°C, 70 0r/min for 20 minutes to obtain a mixture;

S3: First, 50g of A glue and 25g of B glue are mixed and stirred at a temperature of 30℃ and a speed of 20r/min for 1.5 hours, and then mixed and stirred with the mixture at a temperature of 30℃ and a speed of 20r/min for 1.5 hours, and then degassed in a vacuum environment for 5 minutes to obtain a silicone gel;

Wherein, the thermal conductive powder in step S2 includes 527g of spherical alumina, 102g of boron nitride and 1581g of spherical aluminum nitride with a powder diameter of 0.5μm;

The flame retardant in step S2 includes 46g of magnesium hydroxide, 18.4g of methyl silicone resin and 6.9g of polydimelamine dihydrogen phosphate aluminum salt.

1. Used as gas chromatography reagent, thin layer chromatography reagent and catalyst, also used for gas drying, gas absorption, liquid dehydration, etc.

2. Used for moisture-proof, rust-proof, gas dehydration, purification and catalyst carrier, and can also absorb harmful elements in water. Uses: Used as humidity indicator to display the humidity saturation of desiccant, packaging and relative humidity of the space medium in precision instruments and meters

3. Suitable for oxygen production, nitrogen production and natural gas dehumidification processes in fertilizer, steel, natural gas and other industries as dehumidifiers, also used in military industry, ammunition, etc.

4. It is a good reinforcing agent for rubber, and its reinforcing performance is second only to carbon black. It is also used for lubricants, insulating materials, etc.

5. Mainly used for moisture absorption and rust prevention of instruments, meters, equipment, etc. under closed conditions. At the same time, it can intuitively indicate the relative humidity of the environment through the transition of its own color from blue to red after moisture absorption. It can also be used in conjunction with ordinary desiccant to indicate the moisture absorption degree of the desiccant and judge the relative humidity of the environment.

6. Model I ultrapure silica gel: used as the most commonly used normal phase chromatography filler, widely used in the purification of pharmaceutical intermediates and the extraction of natural products. Model II ultrapure silica gel: used in sample pretreatment for the detection of pesticide residues in food and aroma detection in tobacco leaves, etc. Model III ultrapure silica gel: used in silica gel for ROHS testing. Model IV ultrapure-18 filler

7. Silica gel can be used as a dehydrating agent and drying agent, catalyst carrier, coating binder, pulp treatment agent, refractory binder, etc.

8. Used to treat high molecular weight proteins in beer, transformer oil and insulating oil regeneration, gas and liquid drying, etc.

9. Used as an anti-sticking agent for polypropylene and polyethylene films, a thickener for thick paste coatings and unsaturated resins, a flatting agent for powder coatings and furniture paints, and an anti-caking agent for powder materials

10. Widely used as a thickener and matting agent in the coating industry, an anti-sticking agent (opening agent) for plastic films (polypropylene, polyvinyl chloride, polyethylene), and is the main component of the pre-coating liquid for sunscreen drawings, as well as an anti-caking agent and liquid carrier for food and medicine.

Sales hotline:

Scan and consult wechat customer service

Scan and consult wechat customer service